For an industry that hasn’t changed a whole lot in decades, solid rocket motors (SRMs) have had quite a month.

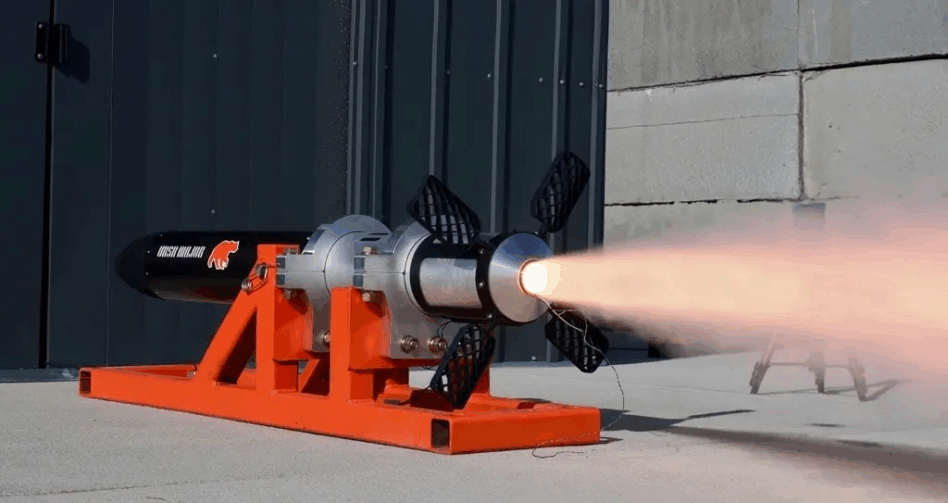

A week after Anduril opened its SRM facility in Mississippi, Ursa Major announced yesterday that it has held successful static tests of its SRM on BAE’s APKWS guided missile. Given the critical gap in supply and demand for SRMs, it sure seems necessity might really be the mother of invention.

SRMs, which we so eloquently described last week as “the things that make missiles go far and fast,” have long been a headache for missile makers, not least because there have been just two primary manufacturers: L3Harris and Northrop Grumman. That’s caused some supply troubles.

- Last year, Rear Adm. Seiko Okano, then-PEO for integrated warfare systems, said that “the bottleneck [in missile delivery] is rocket motors” because the industry is so consolidated.

- Earlier this summer, Raytheon said, “We have to have more sources of supply qualified across a number of my programs for rocket motors” to meet demand.

Motor monopoly: Because of the supply bottlenecks from the SRM old guard, the primes are ditching the adults for a seat at the new kids’ table, with companies like Ursa Major, Anduril, and Firehawk.

Ursa Major, in particular, has been a prime favorite. BAE tapped the Colorado-based company to build SRMs for its Advanced Precision Kill Weapon System (APKWS), a 2.75-inch rocket that turns the unguided Hydra 70 into a laser-guided missile. The company is also working on:

- A new design for the Navy’s Mk 104 dual-thrust rocket motor for its workhorse SM-2, SM-3, and SM-6 surface-to-air missiles.

- An SRM with Raytheon that was successfully flight-tested last December.

- A 5-inch diameter SRM that was tested in May.

“Right now … manufacturers are simply not getting hardware,” Ursa Major co-founder and chief engineering officer Bill Murray told Tectonic in an interview. “We can print these in Ohio and deliver them to Colorado. Companies like BAE and Raytheon recognize that capability.”

“They’re picking us because we have a fundamentally different approach to securing the success of their programs over time, and we have better price points and performance to offer.”

When Murray says Ursa has a different approach, he means it:

- Lynx: Ursa’s SRMs are 3D-printed with their proprietary Lynx Manufacturing System, which uses metallic 3D printing and other technologies to produce different SRM systems on the same production line.

- HLG: Ursa’s Highly Loaded Grain (HLG) propellant, integrated with Lynx, increases the quantity of energetic materials packed into an SRM to extend range.

- They’re also diving into hypersonic and space launch propulsion with their Draper, Hadley, and Ripley engines.

With Lynx, “The same line making the 2.75-inch motor for BAE is the same one we’re scaling to make the 10-inch motors and eventually Standard Missile motors,” according to Murray.

And when he says performance, he means it, too. Ursa said its SRM delivered the APKWS “enhanced range and performance without increasing the motor’s size,” but Murray declined to elaborate. “We can’t really disclose the actual numbers or percentage—but it greatly increased range. And I mean greatly.” We’ll have to use our imaginations for now.

Range for days: That extended range should make the Army and Navy—both already desperate for SRMs as it is—very happy, especially given their role in the future arsenal. “The APKWS is finding many more uses in the modern warfighter environment than it was originally designed for, which is why the Army, Air Force, and Navy are all seeking longer range versions of the platform,” according to Murray.

For next steps, Ursa Major is prepping for a flight test of the APKWS in the fall, which will be the first flight test of their HLG motor. “We’re really excited to field that solution,” Murray said, adding that “BAE is also excited to deploy some enhancements on the APKWS platform.”

Friendly competition: With the level of demand for SRMs far outstripping supply, Ursa Major isn’t worried about Anduril’s foray into the space.

“I’m excited as a US citizen and a taxpayer to see the competition, let alone being a part of it,” Murray said. “Our role right now is to figure out how to solve the manufacturing gaps and to bring innovation and new solutions to an industry that hasn’t seen a lot of challenge for decades.”

“What SpaceX was able to do in the launch industry over the past 25 years, I see happening in the solid rocket motor propulsion industry.”