In case you’re new around here, there’s one thing you should know: the rocket motor industry is infamously concentrated, with just a few old-school suppliers responsible for a whole industry’s worth of energetics.

But in recent years, a few new players have arrived on the scene, promising to do things differently. Firehawk is one of them. The company builds hybrid and solid rocket motors and 3D-prints propellant for hybrid rocket engines, promising to make the industry faster, cheaper, and more distributed. And it seems like the Air Force is getting on board: Today, the company announced that it’s scored a $4M contract with AFWERX for some of their futuristic rocket fuel.

For an industry that hasn’t seen a whole lot of change in decades, it looks like things are starting to get a much-needed shake-up.

Fired up: We’ve covered Firehawk and the concentrated but increasingly busy solid rocket motor (SRM) industry before. SRMs, the things that make missiles go far and fast, have long been a bottleneck in missile production. That’s been a big headache for missile makers and the DoD alike.

Firehawk thinks they can help fix that pinch point:

- They make rocket engines and 3D-print solid fuel grains or propellants, enabling hybrid propulsion (half liquid oxidizer and half solid fuel) that can be a potential replacement for traditional SRMs.

- The company says using additive manufacturing to print the propellant for hybrid rocket engines cuts down on the cost and timeline for energetics production while increasing safety and flexibility.

- They’ve won contracts with the Air Force—including a $4.9M contract with the Air Force Research Lab in June—and the Army to develop and test the hybrid rocket engines for missiles, including a successful test in August with the Army Applications Laboratory (AAL) of its GMLRS-class Firehawk Analog (GFA) hybrid rocket engine system.

- The company also raised a $60M Series C at a $290M valuation back in January and teamed up with Raytheon back in 2022 to integrate the hybrid propulsion system into future missile systems.

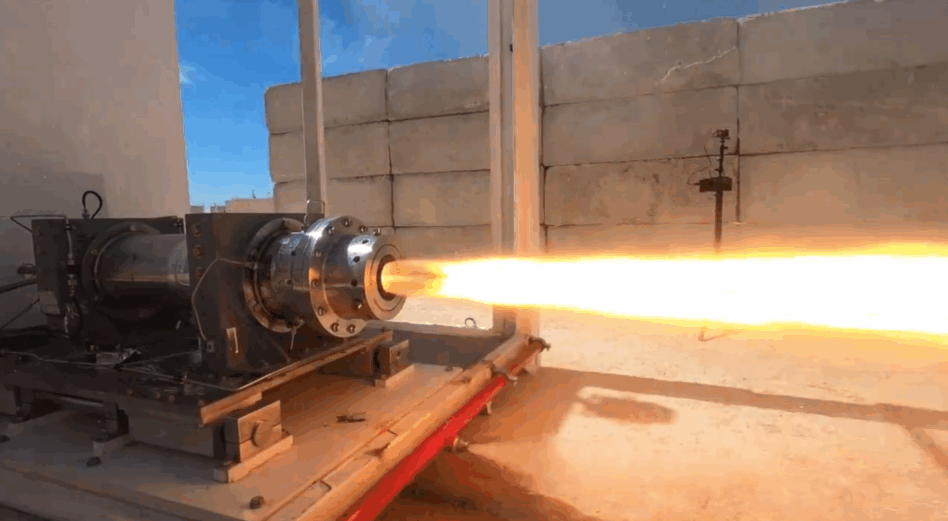

Big flex: This new AFWERX contract will fund Firehawk’s development and hot-fire tests of their 3D-printed, thermoplastic-based propellant, optimized for different thrust profiles and ranges.

Put simply, as Firehawk CEO Will Edwards explained to Tectonic, there are “geometries for different thrust profiles to allow us to extend the range of systems without changing the volumetric metric shape of it all.” They’re focused on the five- to seven-inch air systems, but Edwards says there is a “range of systems that we’re continuing to work with the Air Force on,” hinting at some big partnerships and contracts coming out soon.

A big part of the reason the Air Force (and Army) is so hot on Firehawk is because, according to Edwards, “We’ve cut a 60-day process down to six hours.” They can make the propellant—which is typically really expensive and time-intensive to produce—in bulk and store it, so “when the time comes, you can ask me to start printing propellant for this system or that system with one printer” without changing the assembly line.

Shaking it up: The SRM industry—which is pretty much a duopoly between L3Harris’ Aerojet Rocketdyne and Northrop Grumman—has gotten a bit busier in the past few months. Anduril opened a new SRM manufacturing facility in Mississippi in August, and Ursa Major has also taken an additive manufacturing approach to SRM production that’s proven pretty popular.

Edwards isn’t worried. “Everyone can talk about how they produce and mix their propellant 12 times faster, or whatever the rate is, but they leave off the curing time, which is where 95 percent of the time suck actually is,” he said. “Firehawk’s curing is almost immediate upon the print, so our advantage is production, because we essentially don’t have any curing time.”

For now, Firehawk is focused on “perfecting propellant, because that’s the foundation of everything,” he added. “If you perfect the propellant, you can build the motors, and if you can build the motors, you can build the missile systems. Everything after that’s commoditized.”

With this $4M contract in hand, Firehawk will continue to hone its propellant and invest in expanding its facilities (they opened a big manufacturing and testing facility in Oklahoma earlier this year), which Edwards says will be able to make “thousands of pounds of propellant daily.” Go fast indeed.