What’s AI-powered, has many limbs, and will soon be climbing all over even more of the Navy’s most expensive, mission-critical components?

Gecko Robotics, as it turns out. This morning, the PA-based robotics company announced in an exclusive release toTectonic that it’s officially teaming up with major US Navy supplier Trident Maritime Systems to “deploy advanced manufacturing technologies that expand production of the fleet’s essential components.”

In normal people speak: Gecko’s robots, sensors, and AI-powered Cantilever software will be used on Trident’s factory floors to speed up the production of components for everything from DDGs to subs. The company expects Trident output to increase by 40 percent as a result of the partnership.

“Rebuilding the American industrial base requires new ways of understanding how components are made, and how we unlock the capacity hidden within our supply chain,” Jake Loosararian, co-founder and CEO of Gecko Robotics, said in a statement. “Gecko’s partnership with Trident will rigorously assess each component and build a digital thread that will improve the manufacturing process, ensuring our men and women get the ships and systems they need.”

God of the sea: We’ve covered Gecko before, so let’s start by taking a look at Trident.

The component behemoth isn’t necessarily the kind of sexy defense tech startup we normally write about, but man, oh man, are they everywhere.

- The components producer has “more than twenty production, integration, and service sites supporting the U.S. naval and commercial shipbuilding ecosystem.”

- While they don’t build the ships themselves, they supply and integrate everything from HVAC systems, to propulsion and controls, to shipboard equipment and systems for a huge portion of US Navy vessels—from surface combatants to amphibs to Virginia- and Ohio-class subs.

- Trident is firmly part of the old guard of naval shipbuilding—Gecko basically says it will use its robots and sensors to bring it into the modern era.

Free solo: Gecko is pretty much as far as you can get from an old-school naval components manufacturer. The company was founded by Loosararian and Troy Demmer (now Gecko’s president) back in 2013 to build robots that could revolutionize the way we think about maintenance.

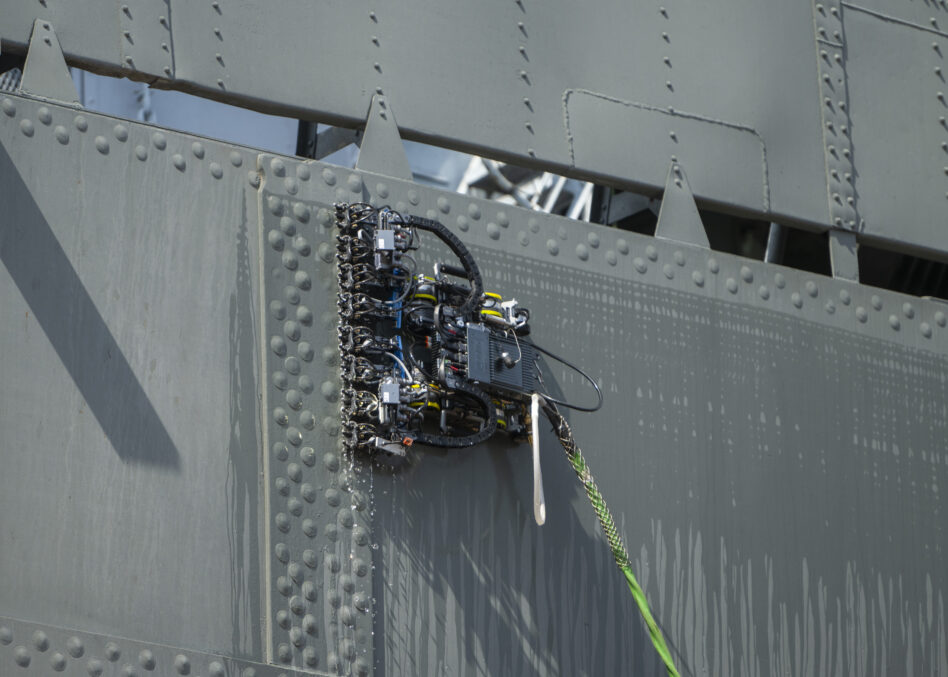

- The company builds climbing, crawling, and swimming robots (yes, really) designed to inspect hard-to-reach infrastructure—anything from far-out power lines to, well, nuclear subs.

- Those robots use ultrasonic sensors and AI (through the company’s Cantilever platform) to detect corrosion, cracks, and structural issues before they become big problems. The whole shebang is sold as a service to customers, which includes the Navy, the Air Force, and grid operators.

- The idea is like a super-charged version of “repair don’t replace.” Cantilever produces 3D visualizations and maintenance insights that help users plan repairs, extend asset life, and avoid downtime.

To visualize this: When speaking to Tectonic last year, Demmer used the example of a ship’s deck. Gecko’s robots can climb all over and sense weak points so that, rather than replacing the whole thing, you can just fix the bits of the deck that might break.

The same logic applies to manufacturing—Gecko’s robots and software can inspect production lines, components, and processes to ensure everything is working as efficiently as possible.

TL;DR: Better use what you’ve got, rather than building it from scratch.

Cash money: Investors and partners have found the idea convincing, to say the least.

Last summer, Gecko raised a whole $125M Series D at a $1.25B valuation, bringing total funding raised to $344.2M (according to Pitchbook data).

- A few weeks later, the company inked a partnership with BPMI, the prime for the Naval Nuclear Propulsion Program (NNPP). That was their first move into manufacturing.

- They’ve also teamed up with L3Harris and HII for aircraft and vessel maintenance.

Puzzle pieces: This new Trident partnership will be most similar to the team-up with BPMI, where the company has seen a 92 percent throughput improvement in the QA process since the partnership, according to Demmer.

- Gecko says its robots and software deployed in Trident facilities “will identify hidden bottlenecks and implement both hardware and software interventions designed for high-mix manufacturing.”

- The goal is to take a pretty disparate production and supplier network and streamline it using AI and robotics.

- The whole thing isn’t just climbing robots—Gecko can also deploy sensors on existing machines to see what’s working and what isn’t.

Gecko’s whole idea is to simply make existing manufacturing capabilities better using robotics and AI. Factories of the future are great, but they take a long time to build.

“It’s great to invest in these green fields, in these future projects, and I think that will take us to the next level,” Demmer said, “But the time to make advancement is now. The time to increase readiness is, you know, using that existing capacity.”

Plus, the more data they have on vessel components, the better they can help maintain the Navy’s fleet. Chicken and egg for the win.