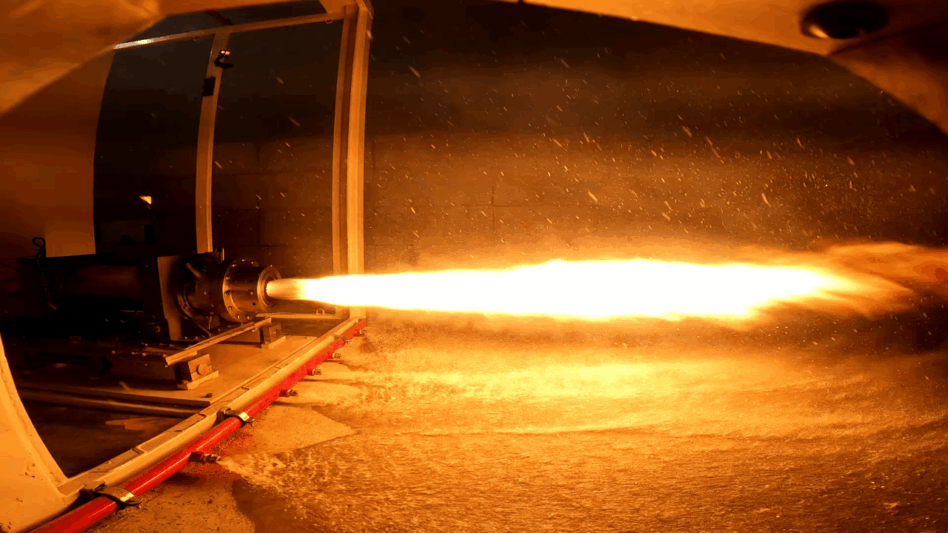

We told you that energetics were having a moment. This morning, rocket motor startup Firehawk Aerospace announced that it has completed a successful flight test of its 3D-printed GMLRS-class analog hybrid rocket engine as part of its ongoing Phase III SBIR contract with the Army Applications Laboratory (AAL).

According to Firehawk, the hybrid rocket system (designed as a stand-in for traditional SRMs on DoD weapons systems) made a vertical ascent of over 18,000 feet and managed to go faster than the speed of sound (Mach 1).

“This milestone proves that hybrid propulsion systems, when paired with advanced additive manufacturing, have a real place in the future of tactical systems,” Firehawk CEO Will Edwards said in a statement.

Go boom: We’ve prattled on about this before, but the solid rocket motor and propellant industry has long had a bit of a supply problem. Production has long been dominated by just a few primes (L3 Harris and Northrop Grumman) who still use techniques very much stuck in the last century.

- Last year, Aerojet Rocketdyne—purchased by L3Harris in 2023—reported it was thousands of rocket motors behind schedule.

- This summer, Raytheon said that the SRM shortage was still limiting missile production.

- DoD leadership has also identified the SRMs as the main bottleneck to making more missiles.

Edwards founded Firehawk Aerospace back in 2019 to bring SRM production into the 21st century. The idea was to take modern manufacturing techniques—like 3D printing—and apply it to solid rocket motor propellant.

- 3D printing, Edwards told Tectonic back in June, takes production time down from weeks to mere hours.

- The company employs a “mobile manufacturing approach” where they can set up mini 3D-printing propellant factories pretty much anywhere it’s needed (think on the frontline).

The company’s SRMs—powered by this 3D-printed propellant—use a unique hybrid propulsion system that combines the 3D-printed solid fuel grain with liquid or gaseous oxidizer. Edwards told Tectonic when we spoke earlier this summer that this makes the motors reusable and more efficient than their traditional counterparts. He also said they’re a lot safer.

Money, money, money: And investors have taken notice. The company raised a $60M Series C back in January at a $290M valuation, bringing total funding to $80.1M. They also inked a partnership with Raytheon ($RTX) back in 2022 to integrate the hybrid propulsion system into future missile systems.

They’ve also scored some DoD contracts, which makes sense considering the government and primes are both kind of freaking out about SRM supply:

- A $4.5M SBIR Phase III with AAL to develop hybrid propulsion tech for systems including GMLR, Javelin, and Stinger. That’s the one this flight test was part of.

- A $4.9M contract with the Air Force Research Lab to develop next-gen hybrid rocket engines for strategic and tactical missiles.

- A $1.2M contract with AFWERX to develop the 3D-printed propellant.

This flight test is the first in a series for the Army. Next up, the company says it will flight-test its Javelin-class and Stinger-class analogs.